Direct-to-Film (DTF) transfer printing is a cutting-edge process offering unparalleled precision and versatility. This method, eliminating traditional rollers, enables complex designs and vibrant colors on various materials, appealing to artists and businesses alike. Ordering DTF transfers online democratizes access, with customers conveniently customizing and receiving high-quality prints for diverse applications. The technology's future looks bright, driven by e-commerce trends and advancements in inkjet technology, promising faster speeds, wider color gamuts, and easier accessibility.

“Discover the future of printing with Direct-to-Film (DTF) transfer technology. This innovative process empowers businesses and creators to order custom prints directly onto a variety of materials without the need for costly set-ups. In this comprehensive guide, we explore the benefits of online DTF services, from seamless product selection to customization options. Learn how DTF printing revolutionizes industries, enhances quality, and opens doors to endless creative possibilities with DTF transfers.”

- Understanding Direct-to-Film (DTF) Transfer: A Revolutionary Printing Process

- The Benefits of Ordering DTF Transfers Online

- Navigating the Process: From Product Selection to Customization

- Unboxing Your DTF Prints: Quality Assurance and Satisfaction

- Applications and Industries Benefiting from DTF Technology

- Future Prospects: Trends Shaping the World of DTF Transfer Printing

Understanding Direct-to-Film (DTF) Transfer: A Revolutionary Printing Process

Direct-to-Film (DTF) Transfer is a cutting-edge printing process that has revolutionized the way we produce high-quality prints. Unlike traditional methods, DTF involves transferring ink directly onto a film surface, eliminating the need for intermediate rollers or plates. This innovative technique offers unparalleled precision and flexibility, allowing for complex designs and vibrant color reproduction. With DTF Printing, images can be swiftly brought to life on various materials, from canvas to metal, opening up a world of creative possibilities.

The process starts with a digital design that is meticulously converted into a format suitable for DTF. This file is then used to create a mask, which acts as a template for the printing machine. During the actual transfer, ink jets precisely deposit pigment onto the film, ensuring every detail is accurately rendered. The result is exceptional clarity and depth in DTf Prints, making them highly sought after by artists, businesses, and individuals seeking unique, high-impact visuals.

The Benefits of Ordering DTF Transfers Online

Ordering Direct-to-Film (DTF) transfers online offers a convenient and efficient way to access this specialized printing service. It eliminates the need for physical visits, saving time and effort. With just a few clicks, customers can browse through various DTF transfer options, compare prices, and place orders from the comfort of their homes or offices. This digital platform provides an extensive catalog of DTF prints, catering to different needs, be it for personal projects, small businesses, or large-scale applications.

Moreover, online ordering streamlines the process by allowing customers to provide specific requirements and customization details. They can select from a range of materials, sizes, and finishes, ensuring they get precisely what they need. This accessibility and control over the ordering process make DTF printing more accessible than ever, fostering creativity and enabling individuals and businesses to bring their visual ideas to life swiftly and effectively.

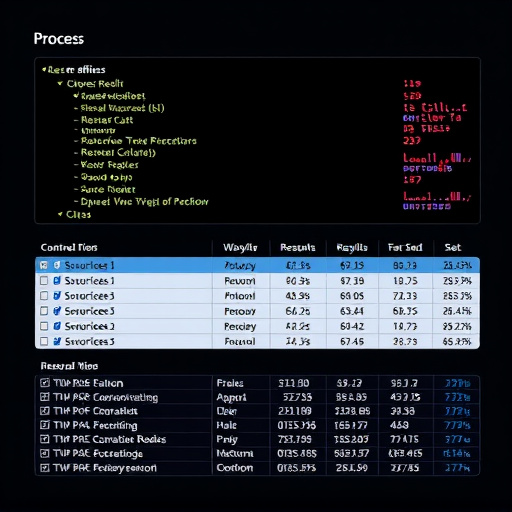

Navigating the Process: From Product Selection to Customization

Navigating the process of ordering a direct-to-film (DTF) transfer product involves several key steps. First, users need to select from a wide range of DTF transfers and prints available on the platform. This includes choosing the specific type of material, size, and quality that best suits their needs. Once the product is selected, the customization phase begins. Customers can upload their designs or artwork, add text, logos, or graphics, and even specify special instructions for printing. The platform offers user-friendly tools to make this process straightforward, ensuring that both beginners and professionals can create customized DTF transfers without any hassle.

After customization, users review their order, confirming all details including dimensions, colors, and finishing touches. This step is crucial to ensure the final product meets expectations. Then, the order is sent for processing, where advanced printing technology and skilled technicians collaborate to bring the design to life on the chosen film. This meticulous process guarantees high-quality DTF prints that can be applied to various surfaces, from clothing to ceramics and more.

Unboxing Your DTF Prints: Quality Assurance and Satisfaction

Unboxing your DTF prints is an exciting moment, marking the culmination of a digital-to-physical transformation. When you receive your order, take a moment to assess the quality of the packaging—it’s designed to ensure your DTF transfers remain pristine during transit. Look for secure wrapping and protective materials that hint at the care taken to preserve the integrity of your prints.

Upon opening, carefully inspect each DTF print for any defects or discrepancies. High-quality DTF transfers boast vibrant colors, crisp details, and flawless resolution. Ensure the image aligns perfectly with the specified dimensions and specifications provided by the service. Satisfied with your quality assessment? Enjoy the satisfaction of holding tangible, professional-grade DTF prints that bring your digital creations to life—ready to be framed, displayed, or incorporated into various projects.

Applications and Industries Benefiting from DTF Technology

Direct-to-film (DTF) technology has revolutionized various industries by offering an efficient and cost-effective method for producing high-quality prints directly on a range of materials, from textiles to plastics and metals. This innovative process allows businesses to streamline their production workflows, eliminating the need for complex intermediate steps. For instance, in the apparel industry, DTF printing enables small batch or custom clothing manufacturers to produce unique designs swiftly, catering to individual customer preferences.

Beyond fashion, DTF technology finds applications in packaging, signage, and even 3D printing. In packaging design, DTF Transfer allows for vibrant and detailed branding on various product surfaces, enhancing visual appeal and product differentiation. Signage makers can create durable outdoor signs with intricate graphics, while 3D printers can utilize DTF to add color and texture to printed objects, opening up new possibilities for artistic expression and functional designs.

Future Prospects: Trends Shaping the World of DTF Transfer Printing

The future of Direct-to-Film (DTF) transfer printing looks bright, with several emerging trends poised to revolutionize the industry. One significant trend is the increasing demand for personalized and on-demand printing solutions. With the rise of e-commerce and online customization platforms, consumers are now expecting tailored products, and DTF printing perfectly caters to this need. This shift towards customization opens up new possibilities for businesses to offer unique, one-off prints, from custom phone cases and clothing to personalized gifts, all delivered promptly.

Additionally, technological advancements in inkjet technology and print heads will further enhance the capabilities of DTF transfer printing. Improved resolution, faster printing speeds, and wider color gamuts will enable the creation of more vibrant and intricate DTF prints. The integration of AI-driven design tools and automated printing processes can streamline the entire workflow, making it more efficient and accessible to a broader range of users, from hobbyists to professional designers.